Our drying solutions are engineered to deliver efficient, uniform, and contamination-free drying for pharmaceutical, cosmetic, chemical, and food applications. Built to cGMP standards, they ensure maximum productivity while maintaining product quality and compliance.

Drying Section

OUR DRYING PRODUCTS

FLUID BED DRYER

- Models: cGMP and Non-GMP

- Application: Drying

- Industry: Pharma, Chemical, Cosmetics, and Food Industries

- Capacity: 1 kg to 500 kg/hr (depends upon requirement)

- MOC: Contact parts – SS316, Non-contact parts – SS304

- Safety: 2 bar construction

- Filter Bag: PC Satin / PP cloth

- AHU: PUF insulated with pre, micro, and HEPA section

- Heating Media: Steam or electrical

- Inlet Chamber: SS304

- Product Container: SS316 with trolley and PU wheels

- Expansion Chamber: SS316 with filter bag housing

- Filter Bag Shaking: Pneumatic

- Filter Bag Up/Down: Pneumatic

- Blower Motor & CFM: Depends upon static pressure

- Sealing: Inflatable / lifting cylinder type

- Pneumatics: Festo / SMC

- Electrical: Standard

- Controls: Semi-automatic and PLC-HMI system

- Options: SFM, SCADA system, 21 CFR Part 11 compliance

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

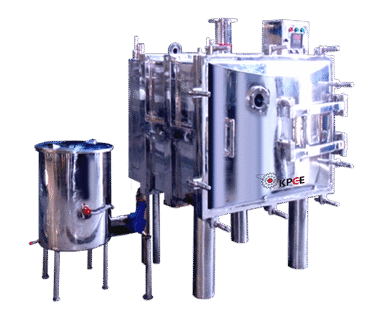

VACUUM TRAY DRYER

- Construction: Double-walled construction, inner made of 16 Gauge SS304 sheet, outer made of 16 Gauge SS304 sheet on 50x50x6 thick angle frame

- Finish: Inside mirror finish, outside matt polish

- Temperature: Maintained at 120°C throughout

- Door: Fully opening with hinges, latch, and handle

- Damper: Manual, electric, or pneumatic operated

- Safety: Rupture disc

- Tray MOC: SS316, size 32 x 16 x 1¼ inches

- Trolley: SS304

- Air Circulation: By fan fitted on the side of the oven

- Motor: Driven by 3-phase, 440-volt electric motor

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

TRAY DRYER

- Type: Most commonly used batch dryer

- Design: Box-shaped construction, loaded and unloaded via a door

- Heating Plates: Several plates mounted one above the other for product trays

- Product Placement: Product placed in trays positioned on heating plates

- Surface Finish: Smooth bottoms on both heating plates and trays for optimal heat transfer

- Heating Medium: Water, steam, or thermal oil

- Plate Spacing: Determined by surface loading and foaming characteristics of the product

- Cabinet Preheating: Walls indirectly preheated by heating plates to prevent retrograde condensation

- Operation: Product introduced and heated at atmospheric pressure

- Drying Process: Begins only after all trays reach uniform temperature and the cabinet is evacuated

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

DOUBLE CONE VACUUM DRYER

- Benefit: Reduces drying time

- Benefit: Eliminates need for re-drying of lumps

- Benefit: Avoids handling and exposure of final product

- Benefit: Produces uniform size dry product

- Benefit: Processes crystalline or amorphous powders prone to lumps

- Benefit: Easy-to-clean internal surfaces ensure product purity

- Benefit: Maintains optimum and continuous vacuum during process

- Benefit: Provides uniform material shuffling over heated cone surface

- Inner Shell/Cone & Contact Parts: SS316

- Steam/Hot Water Jacket: SS304

- Insulation Jacket: SS304

- Cyclone Separator: SS316

- Condenser: Shell & tube type in SS304

- Receiver: SS304

- Discharge Valve: SS316 butterfly type with dummy and hand wheel

- Drive Unit: Enclosed with SS304 covers

- Mechanical Seal: Dry type for vacuum side and water side

- Motor & Control Panel: FLP motor with FLP SS304 control panel

- Digital Temperature Indicators: A) FLP at hot water inlet and outlet B) FLP and dial vacuum gauge in vapour line C) FLP with pneumatic valve at hot water inlet

- Provision: Nitrogen purging/vacuum release with interlock to isolation valve

- Stand/Structure: SS304/MS with SS304 cladding

- Temperature & Vacuum Gauges: Dial type on cone

- Safety Guard/Railing: Telescopic type with FLP limit switch and interlock

- Jacket Safety: Drain plug and safety valve on hot water/steam jacket

- Dust Filter: Pulse jet type inside cone

- Positioning Wheel/Inching Button: For cone positioning

- Drive Mechanism: Gearbox & motor direct coupled; gearbox to cone drive shaft via bull gear–pinion gear

- Extended Shaft: Allows drive unit placement in service zone (if required)

- Vacuum Loading: System for wet material loading into cone

- Finish: Internal – 320 grit mirror polish; External – 180 grit matt finish

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

ENHANCED PRODUCT QUALITY

Ensures consistent, uniform production with precise control over formulation, mixing, and processing.

INCREASED EFFICIENCY & PRODUCTIVITY

Speeds up production cycles with automated and optimized processes.

REGULATORY COMPLIANCE

Designed to meet strict pharmaceutical and cosmetic industry standards (GMP, FDA, WHO guidelines).