We offer a comprehensive range of high-performance mixing solutions designed to meet the stringent demands of the pharmaceutical and cosmetic industries. Our equipment is engineered for precision, efficiency, and GMP compliance, ensuring consistent results every time.

Mixing Section

OUR MIXING PRODUCTS

RAPID MIXER GRANULATOR, HIGH SHEAR MIXER GRANULATOR

- APPLICATION: Wet granulation

- INDUSTRY: Pharma, Chemical, and Cosmetics industries, etc.

- OUTPUT: 2 to 1200 Ltrs/hr (depends upon requirement)

- MODELS: cGMP

- BOWL: Cylindrical, Conical (jacketed and non-jacketed)

- IMPELLER: 3 blades, horizontal profiled inclined

- CHOPPER: 4 blades / multi-blade, longitudinally mounted

- DRIVE: Impeller through reduction gear box

- BOWL LID LIFTING: Pneumatic

- PRODUCT DISCHARGE: Pneumatic

- VENT FILTER: Standard make, 5 microns

- GASKETS: Food grade, silicone

- MOTOR: FLP / NFLP, standard make

- CONTROLS: Standard semi-automatic / PLC-HMI system

- CLEANING: CIP system, WIP system (optional)

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

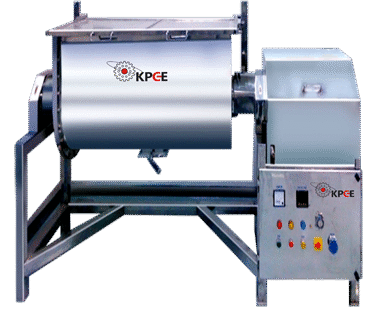

MASS MIXER

- Industry: Pharma, Chemical, Cosmetics, and Food Industries etc.

- Output: 10 to 5000 Liters/hr (depends upon requirement)

- Models: cGMP / NON-GMP

- MOC: Contact parts – SS316, Non-contact parts – SS304

- Blades: Designed for uniform mixing in jig-jog type

- Drive: Through motor and reduction gear box

- Online Spraying: Through peristaltic pump & silicone piping

- Safety Door: SS cover / Acrylic cover

- Tilting Arrangement: Provided for easy unloading of material, operated by hand wheel; powder or granules can be tipped into a container placed conveniently

- Sealing Arrangement: Specially designed self-adjusting sealing system ensures no black particles enter the mixing drum

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

PLANETARY MIXER

- Application: Wet granulation

- Industry: Pharmaceutical, Chemical, Cosmetics, and Food etc.

- Output: 10 to 2000 Liters/hr (depends upon requirement)

- Models: cGMP / NON-GMP

- MOC: Contact parts – SS316, Non-contact parts – SS304

- Type: Standard / VJHSE

- Capacity: 5 Liters to 1000 Liters

- Special Use: For high viscous products under vacuum (VJHSE used for dry powder mixing; bowl lifting through hydraulic)

- Drive: Dual speed motor with reduction gear box and bearing housing (VJHSE PLM provided with Teflon scrapers)

- Controls: Standard / PLC-HMI

“Sift with precision. Deliver with confidence.”

— Vibro Sifter solutions engineered for performance, reliability, and compliance.

ENHANCED PRODUCT QUALITY

Ensures consistent, uniform production with precise control over formulation, mixing, and processing.

INCREASED EFFICIENCY & PRODUCTIVITY

Speeds up production cycles with automated and optimized processes.

REGULATORY COMPLIANCE

Designed to meet strict pharmaceutical and cosmetic industry standards (GMP, FDA, WHO guidelines).