Coating Section

Tablet Auto Coating Machine

Type: Film / Aqueous / Solvent / Enteric.

Industry: Pharma., chemical, cosmetics and food Inds.

Capacity: 1 kg to 500 kg/ hr depends upon requirement

Sizes: 6” to 72”

Coating pan: SS316l construction with 3mm hole/5mm pitch.

Models: Cgmp/non gmp

MOC: Contact parts: ss 316 and non contact parts-SS 304

AHU puff insulated with pre, micro and hepa section.

Heating media: Steam or electrical.

Spray Guns: Standard make like spraying systems ,

spraytech, walther pilot etc.

Baffles: Easily revovable type for cleaning

Air distribution: Through plenums either from top or bottom

Spray arm movement: Pneumatic In built WIP /CIP system

Controls: PLC / Scada system

Scrubber: Dry or wet as required. Magnetic gauge or DP

Transmitters across HEPA and pan, Mimic operation in HMI.

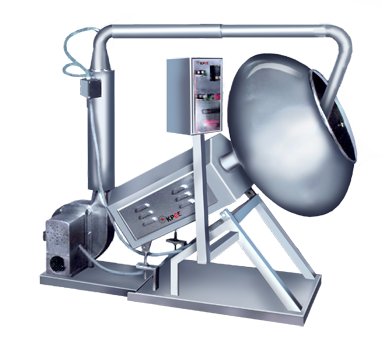

Conventional Coating Pan

Conventional coating pan with very sturdy SS structure.

The Coating pan drive is through standerd make heavy duty worm

reduction gear box & electrical motor by means of belt & pulley

drive fitted on rigid structure. Pan speed can be changed through

variable speed pulley mounted on the shaft of electric motor.

(AC variable frequency drive – optional with extra cost).

Coating pan made of SS 304 / SS316 or SS316 material and

mirror finish polished from inside & outside.

Baffles either welded or detachable (welded are the standard supply

if not specified) provided inside the pan considering production

requirements.

Easy mounting considering changeover of coating / polishing pan.

Separate hot air blower system is provided easy operation.

Digital temperature controller provided with necessary

temperature control device with interlocking for heater function.

Flame proof electrical can be provided with extra cost.