Power Conveying

Mobile Loader

Mobile loaders are mfg. for lifting the storage bins and later

positioning the same at their destination with these devices.

Further, this facility helps in charging the material in order to

process the equipment.

These units are constructed using various standard assemblies

which offer individual solution to each application of solid

dosage manufacturing.

This system is evolved to achieve dust free transfer of in

process materials enhancing CGMP and simultaneously

eliminating laborious manual operation.

The container is then raised or lowered by hydraulic system

with built in safety parameters to discharge the contents in

the process equipment's.

Lifting And Positioning

Applicable for process with Milling, RMG and Sifter.

270 degree Swivelling movement of lifting arm.

Loading Height 1000 mm to 4000 mm.

Hydraulic power pack system for lifting.

If the power goes off, the loader remains where it was.

Limit switches are provided to stop the hydraulic drive

when the stroke is completed.

Simple & Convenient Operation, Changeover, Cleanliness,

Operator protection & ease to maintenance.

There is no dead angle, no concave-convex face,

and no screw on surface.

It's easy to wash tailor-made butterfly valve.

Avoiding dust and cross pollution and materials layering,

optimizing the producing flow.

Capacities: 30 Kg/Hr to 1200 Kg/Hr Industrial Productions.

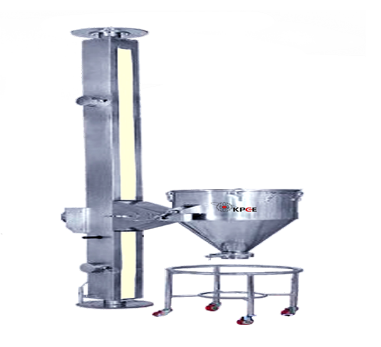

Pneumatic Conveying System

The Conveying system is a method of conveying dry

material in a pipeline through air without any moving parts.

The Machine is necessarily custom made conveying system

and based on product characteristics, particle size,

throughput capacity, number of sources and destinations.

Each Conveying system is designed & customized as per

the application known as custom conveyor system.

The provided solution is assured to be the best pneumatic

conveying system solution for the application.

Being the application experts & pneumatic conveying

system manufacturer, we always assure to deliver.

Root blower is used for positive pressure

Ensure dust free operation, Easy to clean by air pressure

Filter Bag: PP cloth

Discharge: Butterfly valve

Controls: Automatic

Hose: SS or Copper breaded hose pipe for static reason.

CAPSULE HAND FILLING MACHINE

MOC: SS304 or SS316 Easy to operate Size: 00 to 6.

Capacity: 300 holes per minute / filling depends upon operator.

Easy to clean with brush